Quick Answer

How can building owners and facilities teams prevent frozen pipes and cold-weather system failures?

By understanding how water behaves at freezing temperatures and preparing systems in advance. Effective winter water management combines properly insulated and heated piping, thoughtful routing of plumbing and hydronic lines, verified freeze protection controls, and a tight building envelope. When these elements are coordinated early in design and revisited before each winter season, buildings are far less likely to experience ruptured pipes, system shutdowns, and costly emergency repairs.

Cold weather places predictable stress on plumbing and mechanical systems in both multifamily and commercial buildings. While frozen pipe failures often appear sudden, they are almost always the result of known physical behaviors that occur when water is exposed to freezing temperatures without proper protection.

At VP Engineering, our mechanical and plumbing teams design with these conditions in mind, helping architects, developers, and operators protect the life inside their buildings—especially during the most demanding winter weather.

Understanding how water behaves and preparing systems accordingly is critical to preventing damage, service interruptions, and unplanned winter maintenance.

How Water Behaves in Freezing Conditions

Water exhibits several fundamental properties that directly affect building systems during cold weather:

- Moving water is less likely to freeze

- Frozen water expands in volume

- Confined expansion creates significant internal pressure

When water becomes stagnant inside piping exposed to freezing temperatures, ice begins forming at the coldest points. As freezing progresses, expansion generates pressure that can exceed the pipe’s material strength, resulting in cracks or ruptures. Failures often occur away from the visibly frozen section, making diagnosis more complex after the fact.

These outcomes are not anomalies—they are consistent, repeatable, and well understood. Effective winter water management treats them as design constraints, rather than unpredictable events.

Why Flow Can Delay Freezing (But Is Not a Long-Term Solution)

In extreme cold, limited water flow is sometimes used to delay freezing. Flow helps by:

- Introducing warmer upstream water

- Maintaining molecular motion

- Allowing ongoing heat exchange within the pipe

However, continuous flow should be viewed as a temporary mitigation, and not a long-term solution. If a system relies on active flow to prevent freezing, it usually indicates that insulation, heating, or system placement is insufficient for the conditions.

True freeze protection is achieved through thoughtful design, proper detailing, and proactive winterization—not reactive measures once temperatures have already dropped.

Common Causes of Frozen Pipes in Buildings

Most freeze-related failures stem from a small number of recurring conditions:

- Uninsulated or poorly insulated piping in attics, ceiling plenums, exterior walls, and shafts

- Pipes routed through unconditioned or semi-conditioned spaces without supplemental heat

- Loss of heat due to equipment shutdown, control failure, or power outage

- Seasonal or infrequently used fixtures (such as hose bibs or exterior showers) with trapped water

- Building envelope deficiencies that allow cold air to reach vulnerable piping and equipment

These vulnerabilities can exist for years without issue—until a severe cold event exposes them. Designing to minimize these conditions and address them before winter each year is one of the most effective ways to protect both systems and finishes.

Winterization: A Preventive Approach to System Protection

Effective winterization focuses on eliminating conditions that allow water to stagnate or freeze. The goal is to ensure that critical piping and equipment either remains above freezing or is safely drained before exposure.

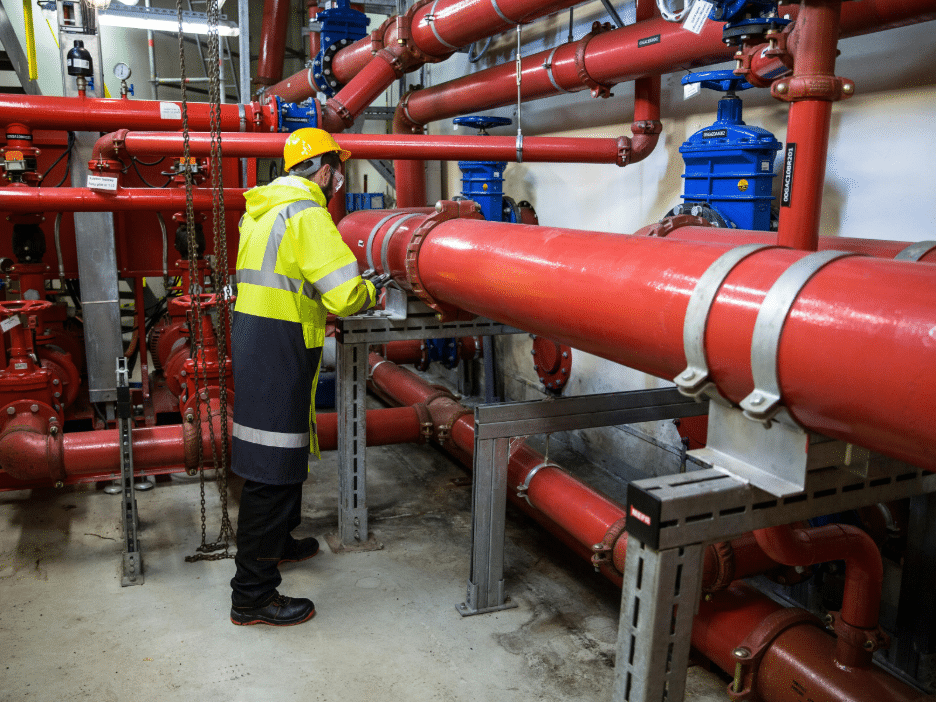

Plumbing and Mechanical Systems

Key measures for plumbing and hydronic systems include:

- Insulating exposed piping, valves, and fittings, especially in ceiling spaces, garages, and exterior walls

- Draining unused or seasonal water lines, such as irrigation systems, exterior fixtures, and seldom-used hose bibbs

- Verifying heat in mechanical rooms and ceiling spaces where piping and equipment are located

- Confirming operation of freeze protection controls and alarms on boilers, pumps, and air-handling units

- Evaluating routing and slope of piping to avoid unintended low points where water can collect and freeze

| Focus Area | Typical Vulnerability | Recommended Winterization Action |

| Garage and parking levels | Exposed or semi-conditioned piping near exterior openings | Add insulation, protect from air movement, and verify operation of unit heaters |

| Ceiling plenums and attics | Piping above ceilings near exterior walls or soffits | Confirm insulation continuity and maintain minimum background heat |

| Seasonal and exterior lines | Hose bibbs, irrigation, exterior showers | Provide drain-down capability, isolate with valves, and clearly tag shutoffs |

| Mechanical rooms | Localized cold spots or louvers near piping | Seal unintended air paths and verify freeze protection controls and alarms |

| Roof-mounted equipment | Condensate and hydronic lines on roof or in exposed chases | Insulate, heat trace where appropriate, and route away from direct cold air |

Building Envelope and Air Infiltration

Water systems are only as protected as the spaces that surround them. Winterization should also address the building envelope:

- Inspect for air leaks near piping penetrations and wall openings

- Ensure doors, louvers, and access panels are properly weather-stripped and sealed

- Verify insulation continuity around mechanical areas, shafts, and exterior wall cavities

- Confirm that vented spaces (such as soffits or attics) do not expose unprotected piping to outside air

Winterization should be completed before freezing temperatures occur. Once systems are already exposed to cold, reactive measures are far less effective and often more expensive.

Why Preparation Reduces Risk and Cost

Frozen pipes rarely fail the moment temperatures drop. The failure process begins earlier, when trapped water and gradual heat loss go unnoticed. By the time damage is visible, repairs and clean-up are already unavoidable.

Proactive winter preparation helps:

- Reduce emergency repairs and water damage

- Protect finishes, equipment, and occupied spaces

- Minimize business disruption and tenant impact

- Improve maintenance planning and budgeting for facilities teams

Cold weather does not create weaknesses—it reveals them. A structured winterization plan turns those potential weak points into managed risks.

Winter Readiness Checklist for Building Owners and Facilities Teams

Before freezing conditions arrive, owners and facilities teams should confirm the following:

- Heat is maintained in all mechanical rooms, riser closets, and critical ceiling spaces

- Vulnerable piping is identified, properly insulated, and protected from direct air movement

- Unused fixtures and seasonal systems are drained and clearly tagged

- Freeze protection controls, sensors, and alarms are tested and documented

- Controlled flow (such as drip lines) is used only as a temporary measure where appropriate

- The building envelope limits cold air intrusion around piping, equipment, and access points

- Emergency response plans identify shutoff locations, priorities, and contact protocols

Preparation protects performance. Winter does not wait—and neither should building systems.

How VP Engineering Helps Design for Winter Conditions

Designing for winter performance begins long before the first cold front arrives. VP Engineering integrates freeze protection considerations into our MEP design services, helping clients:

- Route plumbing and hydronic systems to minimize exposure to freezing conditions

- Coordinate with architects to align system placement with envelope and insulation strategies

- Incorporate appropriate controls, insulation, and monitoring for climate and building type

- Develop details and design standards that support consistent winter readiness across portfolios

For multifamily, senior living, and commercial projects, our goal is the same: systems that remain reliable when conditions are at their most demanding.

FAQ Section

When should winterization planning begin for a new project?

Winterization should be considered during early design, not just before the first operation. Decisions about system routing, shaft locations, and mechanical room placement all influence how vulnerable a building will be to freezing conditions.

If my building meets code, do I still need a winterization plan?

Yes. Building codes establish minimum requirements, but they do not replace proactive operational planning. A winterization checklist tailored to your building type, climate, and systems is still essential.

What types of projects are most at risk during severe cold events?

Buildings with exposed or semi-conditioned parking levels, long exterior corridors, or extensive roof-mounted piping are particularly vulnerable. Multifamily and senior living facilities also carry a higher operational risk because system failures directly impact residents.

If you are evaluating existing vulnerabilities or planning a new project, VP Engineering can help you develop a winter-ready MEP strategy that protects both building systems and the people who depend on them.

Conclusion

Winter water management is not a one-time task; it is a repeatable discipline that aligns design intent, building operations, and long-term performance. By treating freezing behavior as a predictable engineering condition rather than a seasonal surprise, owners and design teams can reduce the risk of ruptured piping, service interruptions, and emergency repair calls.

At VP Engineering, we integrate freeze protection into our MEP design approach so that systems remain reliable when the weather is at its most demanding. Thoughtful routing, appropriate insulation, coordinated controls, and a strong building envelope all work together to protect the life inside. When buildings are winter-ready by design, cold-weather performance becomes one more outcome you can count on—not one you must worry about.